Shelf Sag Calculator

This calculator estimates shelf deflection using real material properties from the article. Sag increases dramatically with span length and decreases with thickness and stiffness.

Important: For spans over 30 inches, it's recommended to add a center support or use a stiffer material to keep sag below 1/16 inch.

Ever put a load of books on a new shelf only to watch it droop after a week? That sagging feeling isn’t just annoying-it can ruin the look of your room and even damage the wall. The secret to staying sag‑free lies in the wood you pick and how you install it. Below you’ll find the wood types that stand up to heavy loads, plus practical tips to keep those shelves level for years.

Quick Takeaways

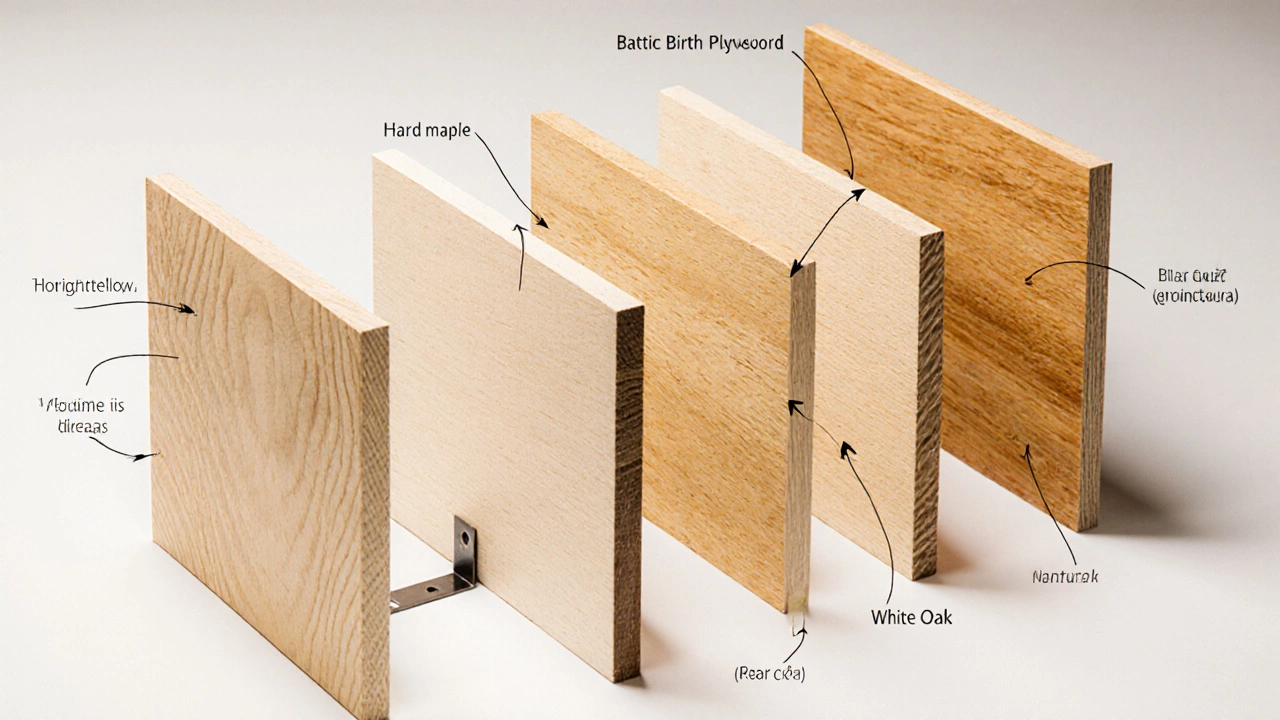

- Hard maple, white oak, and birch are the top natural woods for sag resistance.

- Engineered panels like Baltic birch plywood give excellent strength at a lower price.

- Choose a minimum thickness of ¾‑inch for spans up to 36 inches; go thicker for longer runs.

- Grain direction matters - run the grain horizontally for maximum stiffness.

- Use rear brackets or a solid back panel to halve deflection.

Why Shelves Sag: The Physics Behind Deflection

Wood is a natural composite of fibers that bend when a load is applied. Two key factors determine how much a shelf will flex: modulus of elasticity (E) - a measure of stiffness - and modulus of rupture (MOR) - the breaking strength. The higher these values, the less sag you’ll see.

Another often‑overlooked variable is grain orientation. Wood is strongest when the load runs parallel to the grain. When you install a shelf with the grain running front‑to‑back instead of side‑to‑side, the board behaves more like a thin cardboard strip and sags quickly.

Finally, span (the distance between supports) directly influences deflection. Double the span and you’ll roughly quadruple the sag, assuming the same thickness and material.

Top Sag‑Resistant Natural Woods

Below are the most reliable hardwoods for shelves that need to hold weight without bending. Each entry includes a brief microdata definition that search engines can read.

Hard maple is a dense hardwood (density ≈ 0.75g/cm³) known for a high modulus of elasticity, making it one of the stiffest natural options for shelving.Its tight grain and uniform texture also take finishes well, so you can paint or stain without blotching.

White oak offers a blend of strength (MOR around 100MPa) and moisture resistance, which helps prevent warping over time.Its prominent grain adds a classic look that pairs nicely with both modern and traditional décor.

Birch is a lighter‑weight hardwood (density ≈ 0.65g/cm³) but still delivers solid stiffness, especially the yellow‑birch variety.Its smooth surface takes clear coats well, highlighting its natural pale hue.

Walnut provides good strength and a luxurious, dark finish that many designers love.Although pricier, a thinner board of walnut can match the load capacity of a thicker maple board due to its high E‑value.

Cherry combines moderate stiffness with a warm, reddish tone that deepens with age.It’s an excellent choice for living‑room shelving where aesthetics matter as much as function.

Engineered Panels: Cost‑Effective Strength

If budget is a concern, engineered wood can give you comparable performance without the premium price tag.

Baltic birch plywood is built from multiple thin birch layers glued together, aligning the grain perpendicularly in each layer.This cross‑grain construction dramatically raises stiffness, making ½‑inch Baltic birch almost as strong as a ¾‑inch solid hardwood.

Plywood (standard construction) also resists sag when you choose a high‑grade, three‑ply or more type.Its uniform thickness and low internal stress reduce the chance of warping after installation.

MDF (medium‑density fiberboard) is heavy and flat, which can be an advantage for short spans.However, MDF lacks the grain strength of plywood, so it’s best for decorative, lightly‑loaded shelves under 24 inches.

How to Choose the Right Wood

- Check the density and E‑value. Higher density generally means higher stiffness. Look for woods above 0.6g/cm³ for robust shelving.

- Consider the span. For a 30‑inch run, ¾‑inch solid hardwood or ½‑inch Baltic birch is ideal. For 48‑inch spans, bump up to 1‑inch hardwood or add a center support.

- Match the finish to the project. If you plan to paint, choose a wood with a tight grain (maple, birch). For natural stains, walnut and cherry shine.

- Factor in cost. Hard maple and white oak are mid‑range; walnut and cherry command premium prices. Baltic birch offers a budget‑friendly alternative with similar performance.

- Mind the moisture environment. In humid rooms (e.g., bathrooms), select woods with natural resistance (white oak) or use sealed engineered panels.

Installation Tips to Keep Shelves Rigid

- Mount brackets so the inner edge of the shelf sits on the bracket lip - this adds a few millimeters of leverage against sag.

- For long spans, add a rear cleat or a thin back panel (½‑inch plywood) that ties the two sides together, effectively halving deflection.

- Always orient the grain horizontally (parallel to the wall) unless you deliberately want a decorative vertical grain look and accept more flex.

- Pre‑drill screw holes to avoid splitting the wood, especially near the ends where stress concentrates.

- Apply a clear sealant or finishing coat to reduce moisture absorption, which can cause swelling and increased sag.

Quick Comparison of Top Shelf Woods

| Wood | Density (g/cm³) | Modulus of Elasticity (GPa) | Typical Cost (USD/ft³) | Best Span (inches) for ¾‑in board |

|---|---|---|---|---|

| Hard maple | 0.75 | 13.0 | 6-8 | 36 |

| White oak | 0.71 | 12.5 | 5-7 | 34 |

| Birch | 0.65 | 11.0 | 5-6 | 32 |

| Walnut | 0.64 | 11.5 | 9-12 | 34 |

| Cherry | 0.60 | 10.5 | 8-10 | 30 |

| Baltic birch plywood | 0.65 | 12.0 | 4-5 | 38 (½‑in) |

| Standard plywood | 0.60 | 10.0 | 3-4 | 34 (¾‑in) |

| MDF | 0.70 | 9.0 | 2-3 | 24 (½‑in) |

Common Mistakes That Lead to Sagging

- Using ½‑inch solid wood for spans over 30 inches - the board simply isn’t thick enough.

- Ignoring grain direction - a vertical grain board will flex up to 50% more.

- Overloading shelves with uneven weight distribution; heavy items should sit near the bracket.

- Skipping a rear support on long runs; a thin back panel adds critical shear resistance.

- Choosing low‑grade plywood with voids; voids create weak spots that buckle under load.

Frequently Asked Questions

Which wood is the strongest for shelving?

Hard maple tops the list for pure strength and stiffness, followed closely by white oak and birch. These hardwoods have the highest modulus of elasticity, meaning they bend the least under load.

Can I use MDF for a kitchen pantry shelf?

MDF works for short spans (up to 24 inches) and light loads like spices or dishware. For heavier pots, choose a denser hardwood or a ½‑inch Baltic birch panel.

How far apart should brackets be placed?

A good rule of thumb is a bracket every 24-30 inches for ¾‑inch hardwood. If you go wider, add a center support or increase board thickness.

Is a finished surface important for preventing sag?

Finishes don’t change the wood’s structural stiffness, but a sealant protects against moisture swelling, which can indirectly cause more flex. Paint or clear coat all shelves for longevity.

Should I orient the grain vertically for aesthetics?

Vertical grain looks striking, but expect up to 30‑40% more sag. If you love the look, compensate with a thicker board or add extra brackets.

Choosing the right wood and installing it correctly takes a bit of planning, but the payoff is shelves that stay flat, look great, and last decades. Whether you pick hard maple for premium strength or Baltic birch plywood for budget‑friendly durability, the key is matching material, thickness, and support to the load you expect.